What is brucite?

Brucite is a unique phenomenon in nature - both as a natural resource and in terms of its geology. The available deposits of brucite, which has a higher magnesium content than any other magnesium mineral, are much larger than was previously believed. Brucite is a rock-forming chemical found in rock formations of the same name, and also in brucite marbles- penkatite and predazzite.

The practical applications of this useful mineral were only discovered in the 1970s. Before the discovery and exploration of the brucite deposits in the Lesser Khingan, the largest of which are the Kuldur and Savinsky deposits, the only known reserves of the mineral in the USSR were found in metamorphic carbonate rocks strata near Lake Baikal and in Satka and Yakutia, and also in a number of ultrabasic formations in the Urals, which were of little commercial interest.

There are very few pure brucite deposits in the world - a few are known in the USA and in China, but these are much less productive than the deposits in the Lesser Khingan, and the quality of the extracted mineral is lower.

The main consumers of brucite are the USA, China and Canada. In Russia demand for brucite is only now beginning to develop.

Main identifying qualities and physical and chemical properties of brucite

-

Chemical formula – Mg(OH)2

-

Appearance – it is a dense, crystalline mineral, occurring in the form of lamellate and flaky, or sometimes fibrous aggregates

-

It may be white, grey, bluish-green, brownish or yellow in color.

-

It has a mother-of-pearl or glassy sheen.

-

Crystalline form - rhombohedral

-

Impurities – Mn, Fe, Ca

-

Varieties - nemalite, ferrobrucite, manganese-bearing brucite

-

Chemical components - MgO – 69%, H2O – 31%

-

Density 2.4 g/cm3

-

Hardness, 2.5 - 3.0 on the Mohs scale

-

Brittleness - it breaks up into flakes or fibers

-

Luminescence - appears blueish or dark red in color under UV light

-

Thermal dissociation temperature 0°C- 490°C

-

Solubility — dissolves in acids

Varieties of brucite

A number of different varieties of brucite occur, including nemalite, ferrobrucite and manganese-bearing brucite.

The magnesium in brucite is often found mixed with iron, forming ferrobrucite, or manganese, forming manganese-bearing brucite. Manganese-bearing brucite is a reddish brown in color.

Nemalite, a fibrous asbestos-bearing form of brucite, is also found.

History of the discovery of brucite deposits in Russia

At the beginning of the 1960s the Territorial Geological Directorate for the Far East was instructed to identify sources of raw materials for the production of cladding materials, either by discovering new deposits or reassessing existing ones.

In 1965 B.A. Pelyukhovsky discovered the Kuldur brucite deposit while searching for marble deposits in the Obluchensky district of the Jewish Autonomous Region. In 1966-68 exploration work was conducted there and industrial extraction from the deposit began. The rapid development of the deposit was due to a number of factors: the exceptional purity of the brucite, the favorable economic and geographical conditions, the urgent demand for this mineral, and the importance attached to its development by the Territorial Geological Directorate for the Far East.

In 2021 geological exploration work was performed on the South bank of the Kuldur deposit, in order to extend the available reserves, and according to initial estimates the newly discovered reserves contain an additional 1.8 - 2 million tons of brucite, which will extend the working life of the deposit by 5 to 7 years.

Following the opening of the Kuldur deposit, the search for other mineral sources in the region continued. In the early 1970s the South Khingan field crew, led by V.V. Uspensky and S.V. Kuzmin carried out exploration work in eight different sites in the Oktyarbrsky and Obluchensky districts of the Jewish Autonomous Region, in Khabarovsk Krai. In the Oktyarbrsky district, on the upper stretches of the Samara river, they discovered the Savinsky deposit, the world’s largest known brucite deposit by estimated reserves.

However the Savinsky deposit was in a remote and little explored area and lacked the necessary infrastructure, and it was not possible to start developing it at that time.

Some time later, in the 21st century, the management of the Brucite+ Group took an interest in this deposit. In addition to its vast brucite reserves, which can yield up to 500,000 tons of the mineral per year, the area is conveniently located, being fairly close to new markets in Southeast and East Asia. In 2019-2021 further exploration work was carried out at the deposit, and at the beginning of 2022 a Feasibility study will be concluded in respect of the current status of the exploration and the reserves will be added to the balance maintained by the State Reserves Committee of the Russian Federation. The current reserves of brucite ore in the Savinsky deposit are estimated at 33 million tons.

Areas of application

Because of its unique qualities, brucite has applications in a wide range of fields in both the manufacturing and agricultural sectors.

Metallurgy

One of brucite’s applications is in the metallurgy sector. Magnesium flux is widely used in convertor and electric-furnace steelmaking and in the agglomeration and blast-furnace process. The use of brucite-based flux helps increase the quality of the smelted steel, extend the service life of the converter lining, decrease the cost of the finished steel and reduce the environmental impact of the production process.

Flame retardants

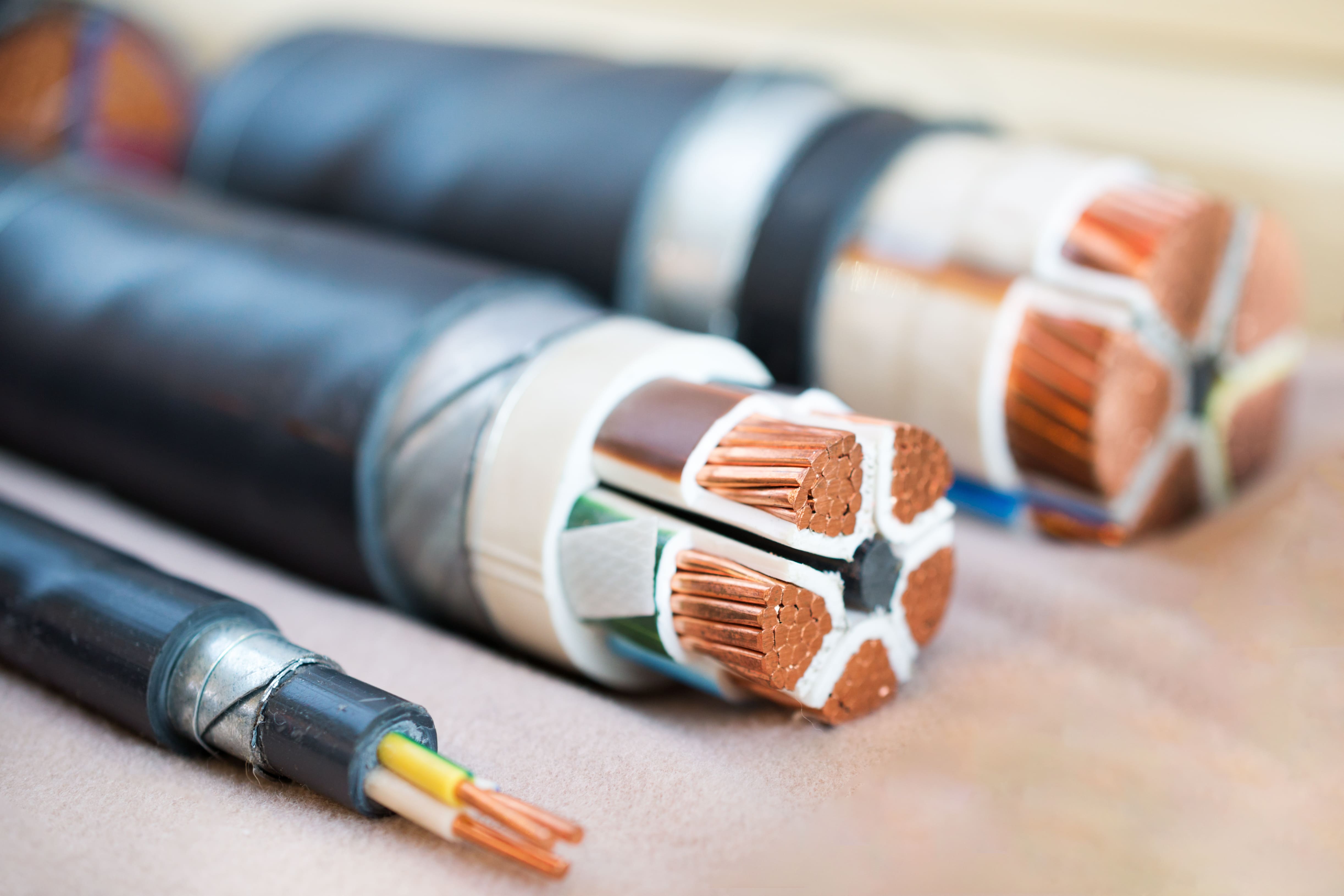

Brucite is used to produce mineral flame retardants. Magnesium hydroxide neutralizes toxic gases released during combustion, significantly reducing smoke generation. Due to its excellent refractory properties magnesium hydroxide promotes the formation of a strong protective char during combustion, preventing the formation of dangerous burning droplets. It’s application as a single flame retardant optimizes the cost of the core compound, increasing productivity and reaching the highest grades of fireproof classification. Brucite is used in the manufacture of PVC and HFFR cables, aluminum composite panels, bitumen and TPO roofing membranes and engineering plastics.

Agriculture

In the agricultural sector brucite is used in the manufacture of natural fertilizers, complex NPK-type fertilizers, and animal feed additives. It is used to manufacture fertilizers for foliar nutrition for crops during the growing season in order to normalize plant metabolism, increase yield, nutritional value of products, and increase plant resistance to diseases in adverse environmental conditions. Brucite in the products used for soil nutrition helps to promote plants’ nutrient uptake through their root systems and improves the soil quality. When used in complex fertilizers, brucite increases their efficiency, neutralizes excess acid during the production process, reduces caking and porosity and makes the fertilizer granules harder. Brucite plays an important role in livestock farming, as it increases the availability in the diet of cattle, pigs and chickens.

Brucite is also used in the manufacture of ammonium nitrate. It helps to reduce caking and porosity in the finished fertilizer and improves its color, makes the granules harder and ensures an optimal granule size.

The environment

Brucite is known to have a higher magnesium content than any other industrially-used magnesium-bearing mineral (up to 65%MgO), and this makes it a highly effective agent for wastewater treatment and flue-gas desulphurization.

Brucite-based products are used in concentrated suspension form to neutralize acidic effluents, precipitate heavy metals, reduce hydrogen sulfide emissions and improve filtration properties of treated sludge, often producing lower levels of solid waste. When they are used in scrubbers to filter exhaust gases, magnesium sulfate, a commercially valuable chemical, is formed as a by-product of the reaction.

Manufacturing

In the manufacture of halogenated rubber, magnesium oxide is added: its high surface area allows it to absorb any released acids and it reduces the speed of vulcanization, thus making the rubber compound safer during processing. Brucite is therefore a valuable component in the manufacture of rubber goods, such as tires, cables etc. Highly active magnesium oxide is also used as a thickening agent in the manufacture of Bulk Molding Compound and Sheet Molding Compound (BMC and SMC) paste.

In the cellulose-based paper industry, brucite, an environmentally harmless chemical, is now replacing more toxic substances. Thus magnesium hydroxide is now used instead of caustic soda and magnesium sulfate in the alkaline bleaching and oxygen disinfection of the cellulose. Brucite does not corrode and presents no danger to human health or the environment.

Brucite products

-

EcoPiren® is a mineral smoke suppressant and flame retardant for use in polymer compounds. It makes polymer-based materials more fire resistant, and reduces burning droplets formation.

-

AgroMag® is a range of products used in the manufacture of natural fertilizers, complex fertilizers, animal feed and feed premixes. The use of AgroMag® products in crop and livestock farming can significantly increase the quality of output.

- MagTreat® is a brucite-based suspension for exhaust gas cleaning in scrubbers and wastewater treatment. MagTreat® is non-toxic and can entirely replace toxic chemical reagents, thus minimizing harm to the environment.

-

MagPro® is an acid scavenger and vulcanizing agent used in the manufacture of halogenated rubber products and pneumatic tires, and as a thickening agent in the manufacture of BMC and SMC composites.

-

BleachMag® is a suspension for use in the bleaching of cellulose, as an alternative to chlorine bleaches.

-

FluMag® is a brucite-based magnesium oxide-rich flux used in iron smelting and steelmaking in an oxygen converter, in electric furnace steelmaking, agglomeration and blast-furnace processes, as well as for agglomerate production.

-

MagAdd® is a primary material used in the production of magnesium sulfate, nitrate, chloride, stearate and other magnesium compounds.

Sources

- Minerals and mineral deposits in Russia

- okamnyah.ru

- Kamnevedy

- Database of mineralogy

- Catalogue of minerals

- kristallov.net

- Brucite+

- Mindat.org

- Birobidjan Region Sholem Aleikhem Universal Scientific Library

- Agrobusiness

- Ecology of Russia

- Mineral Website

- Scientific developments / Sorptive Properties of brucite and brucite-based clay compounds

- Science Direct

- White Gold of the Jewish Autonomous Region