Traditionally, compound formulations of fire resistant halogen-free cable sheath are based on the use of chemically precipitated aluminum hydroxide (ATH). It provides an excellent set of physical and mechanical properties, good processability and fire resistance.

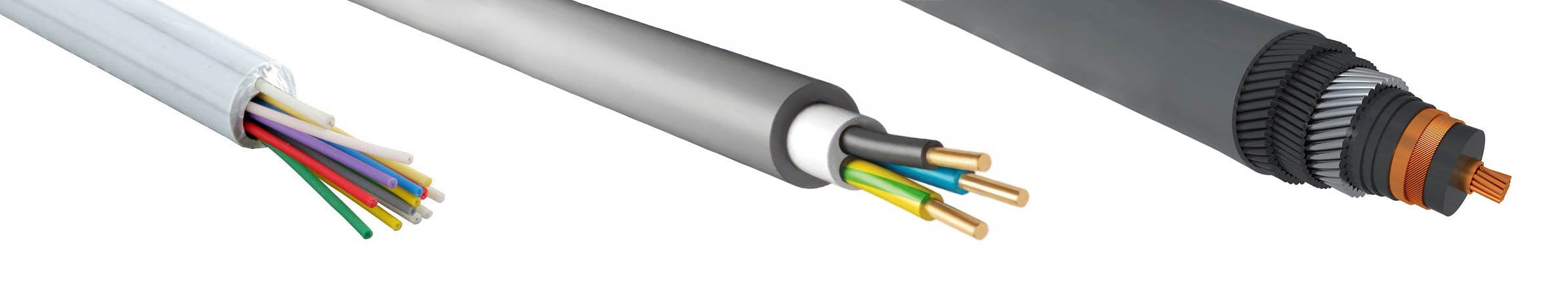

Today, however, such classic formulations are increasingly rare due to cost and the far advanced differentiation of materials for specific tasks. It can be illustrated by an example presented in Figure 1: there is a wide variety of cable designs, each of which (in the simplest case) meets the uniform standards on fire safety.

It is not necessary to make all layers of the cable from equally "averagely" flame-resistant materials. The fire resistance of the layers can and should be differentiated. For example, the insulation of thin conductors today is often made of unfilled cross-linked polyethylene, which can be applied to the core at speeds of more than 500 m/min, but which has no fire resistance at all. Such insulation needs to be protected by a "powerful" barrier such as a highly filled layer of filler.

When using the described approach, the "power" of the flame retardant system in each layer should be either increased or decreased against the original standard that is based on precipitated aluminum hydroxide.

It is not difficult to cope with the "deterioration" of fire resistance; it is just sufficient to replace the necessary part of aluminum hydroxide with micronized calcium carbonate. High quality grades of calcium carbonate have a narrow particle size distribution and high whiteness, as well as ensure perfect processability both in case of compounding and in case of sheathing.

On the other hand, the situation is much less evident with "improvement" of fire resistance. The initial formulation already contains 60-65% of filler, and that is why it is impossible to add flame retardant additionally because of the drastic deterioration of physical and mechanical properties and processability. Thus, we need either to look for synergistic additives or replace aluminum hydroxide with a more effective flame retardant.

To date, the following solutions to this problem are being implemented in the industry:

-

Combining precipitated aluminum hydroxide with natural magnesium hydroxide (brucite);

-

Complete replacement of precipitated aluminum hydroxide with natural magnesium hydroxide (brucite);

-

Combining precipitated aluminum hydroxide with nanoclay and other fillers having lamellar structure with high plate area to its thickness ratio;

-

Combining both hydroxides with phosphorus-based organic flame retardants.

Of the four options, the first one is the most widely used in the domestic cable industry as the easiest to perform. Let’s take a closer look at it.

Combination of ATH and brucite

The main disadvantages of ATH are its "tenderness" during processing and very brittle porous coke formed after its thermal decomposition. Processors successfully overcome the first disadvantage by using modern equipment that allows them to accurately control melt temperatures.

The second one is leveled by adding brucite. Magnesium hydroxide decomposes following the same chemical mechanism, but it also has a very strong ash residue and stabilizes the ATH coke eliminating dripping and reducing the area damaged by combustion by a multiple (Table 1) In addition, when using such a combination, there takes place a staging effect: the temperature range in which the flame retardant system works effectively (180-400°C) is expanding. ATH and brucite can thus be considered synergists for each other.

| Compound according to cable sheath formulation 62% ATH |

Compound according to cable sheath formulation 50% ATH + 12% EcoPiren ® 3,5С |

||

|---|---|---|---|

|

|||

| Heat release (THR), kJ | 5.3 |

1.3 |

|

| Smoke emission (TSP), m2 | 24.3 |

5.7 |

|

Brucite is a natural material, and that is why on the one hand is less expensive than ATH and on the other - has a slightly worse processability. Therefore, the share of brucite in the combination with ATH is determined by the balance of the set of processability and physical-mechanical properties of the compound with its economic component. To achieve a synergetic effect, it is sufficient to introduce 10-15% of brucite, which weakly affects the set of properties and processability of the compound (Table 2).

| Indicator | 62% АТН |

50% АТН + |

31% АТН + |

|---|---|---|---|

|

Density, g/cm3 |

1.49 |

1.49 |

1.49 |

|

Melt flow index at 150°C, 21.6 kgf, g/10 min |

10 | 7 | 5 |

|

Tensile strength, MPa |

12.3 |

12.0 |

14.0 |

|

Braking elongation, % |

200 | 180 | 150 |

|

OI, % О2 |

38 |

38 |

36 |

From geology to innovation,

Brucite+